By Design Tech Solutions — Building Plant Rooms That Work Long After Handover

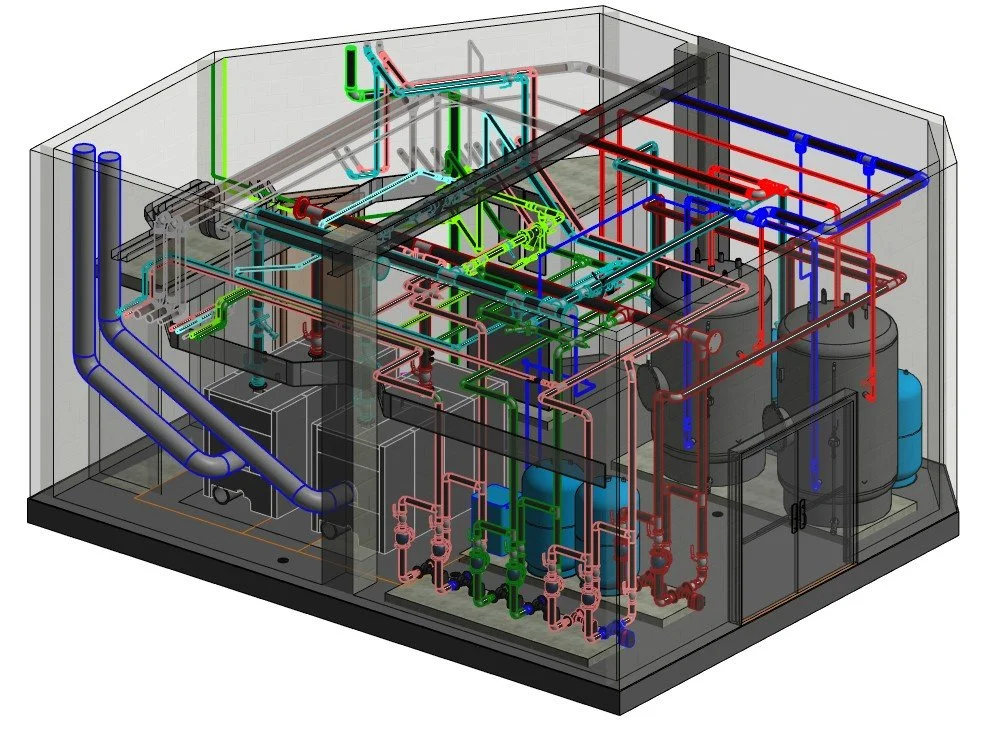

Introduction: A Great Design Is One You Can Service

It’s easy to design a plant room that looks good on paper. But if it’s difficult to service, access, or maintain — it won’t perform over time.

That’s why at DTS, we design for the whole lifecycle of a heat network energy centre. We work with your FM team or M&E contractor to ensure all equipment is accessible, labelled, and logically placed for efficient maintenance.

Why Access & Maintainability Matter

Reduced Downtime

Quick access to valves, pumps, and controls helps fix faults fast and avoid service disruption.

Compliance with CIBSE & HSE Guidance

Plant rooms must meet minimum clearances, airflow, and safety standards — or risk fines and failures.

Lower OPEX Costs

Efficient servicing means fewer engineer hours, fewer callouts, and less overtime.

Smoother Handovers

Commissioning and maintenance manuals are easier to follow when the layout makes sense.

What We Design Into Every Plant Room

Access Zones

We leave the right clearances around all maintainable components: pumps, valves, controls, panels, strainers, and flues.

Logical Labelling & Documentation

We name and reference each component to match commissioning, maintenance, and fault-handling workflows.

Safe Working Routes

We avoid overhead conflicts, floor clutter, and ladder-only access to critical components.

Space for Replacement

We plan access for replacing large items like pumps, HIUs, or tanks — including door width, ceiling height, and turning space.

Lighting, Drainage, & Safety Considerations

We advise on lighting levels, emergency access, bunding, and working-at-height risks in conjunction with the design team.

Key Maintenance-Heavy Elements We Prioritise

Circulators and inverter drives

Isolation and balancing valves

Control panels and alarm resets

Dirt separators and strainers

Flue terminations and safety discharges

Local BMS / SCADA access points

FAQ

Let’s Design for the Real World

If a plant room is hard to service, it’s hard to trust. DTS builds access, safety, and maintenance into the design from day one — so nothing slows you down later.

RELATED READS

Explore our detailed guides on designing effective, future-ready district heating systems. Each article is written to help clients, developers, and stakeholders understand what great network design looks like in practice.