By Design Tech Solutions — Planning for 10, 20, 30 Years of Performance

Introduction: Design for Day One. Plan for Year Twenty.

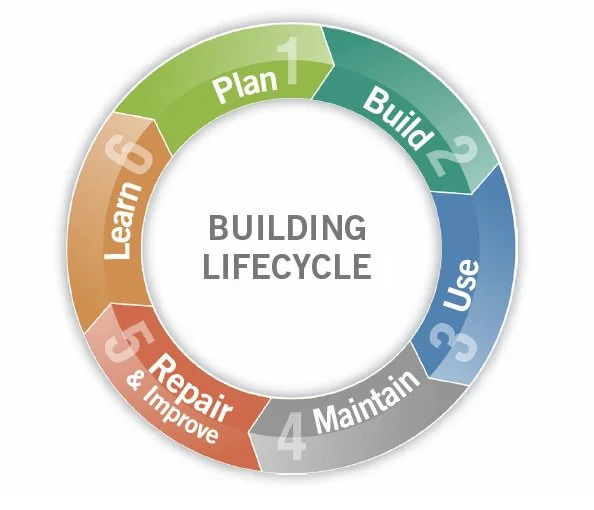

Heat networks are long-term assets. But without a maintenance and lifecycle plan, even well-designed systems can degrade — leading to inefficiency, high costs, and user dissatisfaction.

DTS works with clients to ensure their network not only launches smoothly but stays efficient and reliable long after the ribbon is cut. We provide preventive maintenance strategies, lifecycle costing, and forward-planning to keep systems running and budgets controlled.

Why Lifecycle Planning Is Essential

Reduce Emergency Callouts

Proactive maintenance reduces system faults, downtime, and urgent repair costs.

Control Whole-Life Cost

Understanding component lifespan and replacement cycles supports long-term budgeting.

Improve Operational Efficiency

Tracking performance over time highlights inefficiencies and drift — allowing planned intervention.

Align with ESG & Compliance Goals

Lifecycle visibility supports energy reporting, carbon targets, and funding commitments.

DTS Lifecycle Strategy Services

Planned Maintenance Scheduling

We help create schedules based on manufacturer data, risk profiles, and seasonal demands.

Lifecycle Cost Forecasting

We estimate long-term CAPEX and OPEX requirements — including plant replacement, insulation, valves, meters, and BMS.

End-of-Life & Retrofit Planning

We assess when equipment should be reviewed, upgraded, or replaced to stay efficient and compliant.

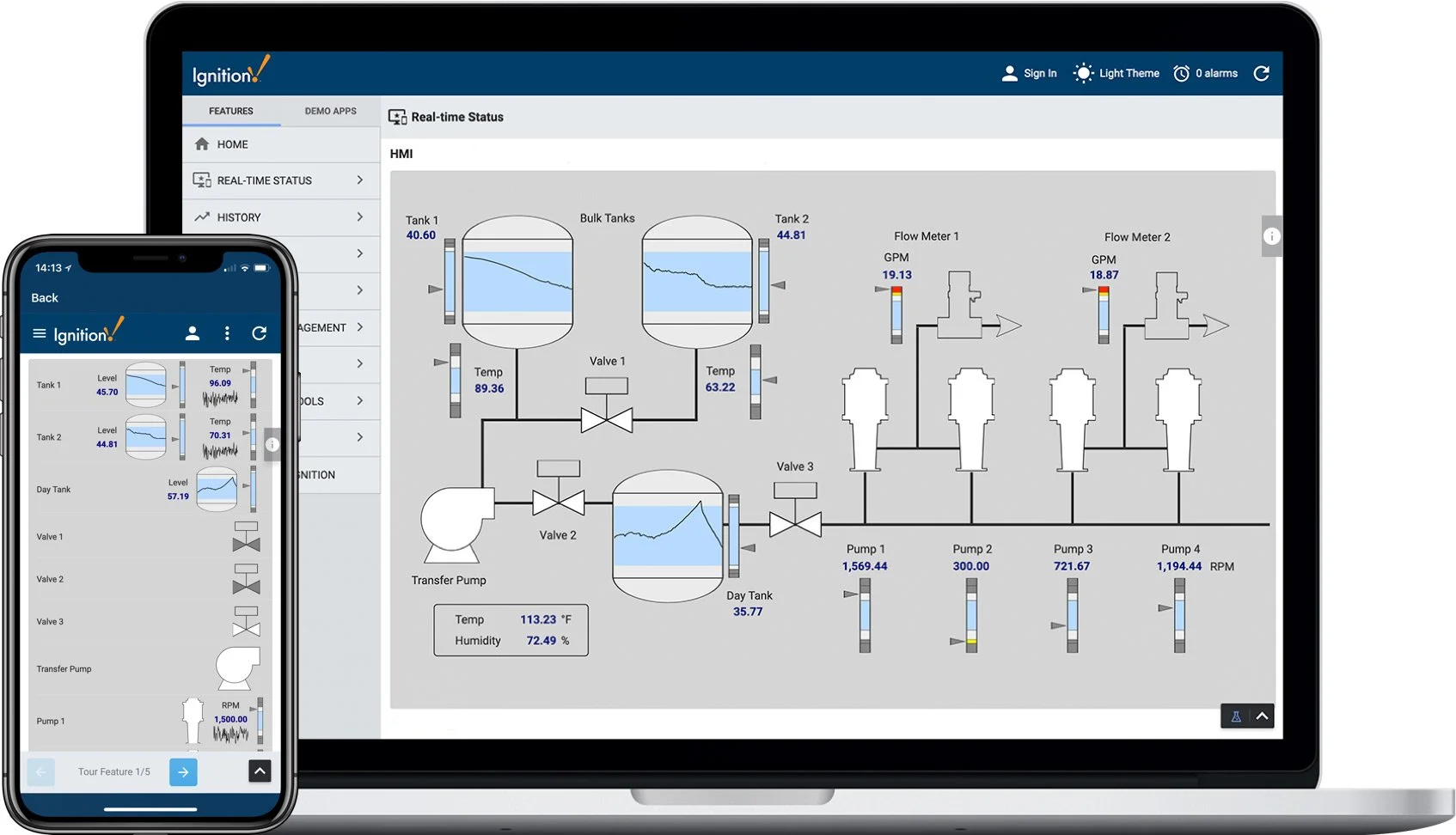

Data-Driven Performance Reviews

We support clients in analysing operational data to inform maintenance cycles and investment priorities.

Futureproofing Design Choices

Our upfront designs consider long-term access, modularity, and control adaptability — reducing retrofit risk.

Key Assets We Help Manage

Pumps, valves, and sensors

Heat pumps, boilers, CHP

Thermal storage and expansion kits

Controls, panels, and wiring

Insulation, meters, and risers

Access zones and safety equipment

FAQ

Plan Ahead. Save Later.

DTS helps heat network owners avoid reactive repair cycles — through smart, strategic maintenance and lifecycle planning that supports long-term performance and cost control.

RELATED READS

Explore our detailed guides on designing effective, future-ready district heating systems. Each article is written to help clients, developers, and stakeholders understand what great network design looks like in practice.