By Design Tech Solutions — Using Digital Tools to Build Smarter Heat Networks

Introduction: Why Digital Twins Matter in Heat Networks

The complexity of modern heat networks requires more than just line drawings and estimates. As networks grow in scale and interact with other infrastructure, the risk of inefficiencies, delays, or design conflicts increases.

This is where digital twins come in — offering a way to visualise, test, and optimise a network long before construction begins. At DTS, we integrate digital twin thinking into every stage of our design process.

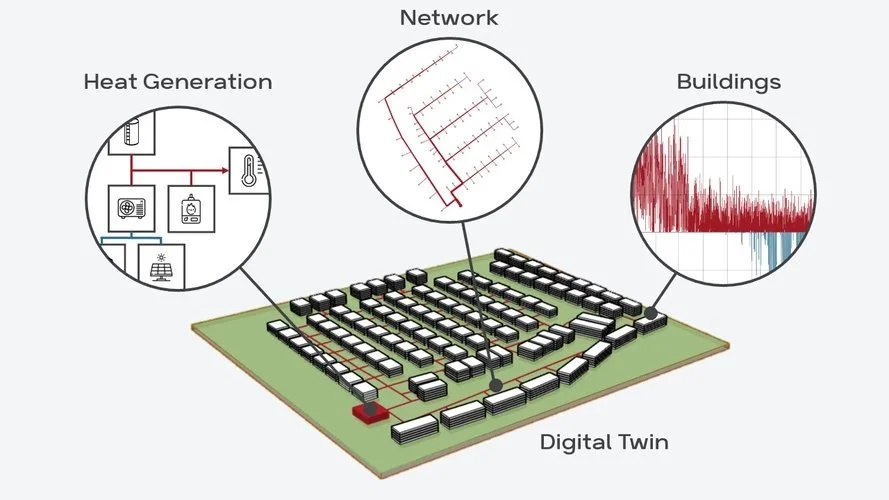

What Is a Digital Twin?

A digital twin is a dynamic, digital replica of a physical system — in this case, a heat network.

It includes:

3D geometry and layout (from BIM or CAD models)

Metadata on flow, temperature, and material performance

Integration with controls, zoning, and energy centre logic

The ability to simulate performance or test scenarios before build

Why Digital Twins Are Useful in Heat Network Design

Clash Detection & Routing

Avoid utility conflicts and unbuildable routes by simulating trench layouts, clearances, and elevation changes in 3D.

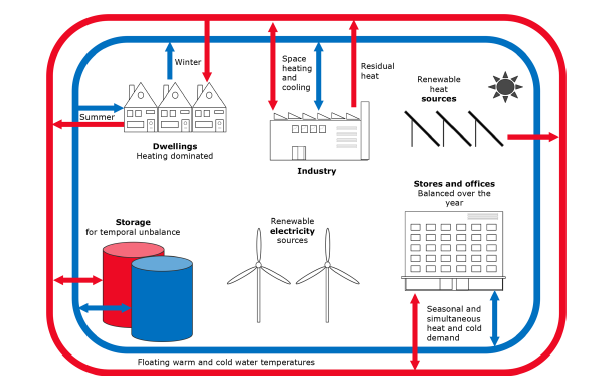

Thermal Performance Modelling

Assess heat losses, temperature drop, and flow dynamics across the system to optimise efficiency and insulation levels.

Design Coordination

Overlay with architectural, structural, and M&E models to ensure the heat network integrates with the wider project.

Smart System Testing

Evaluate control sequences, load profiles, and operational settings virtually — reducing commissioning risks.

Client & Stakeholder Visualisation

Use the model to explain design choices, zoning, and phases to non-technical audiences (e.g. planning teams, funders, councils).

DTS Capabilities in Digital Twin Modelling

CAD + Revit Integration

Our designs are built in 3D from the outset — enabling seamless transition to digital twin simulation.

Layered Data Mapping

We incorporate flow rates, pipe types, insulation values, and control logic into the model.

Smart System Logic Embedding

We simulate how heat pumps, pumps, and control systems will behave across various operating conditions.

Simulation-Ready Outputs

We provide models suitable for LCA, energy modelling, and commissioning tools.

FAQ

When to Use a Digital Twin

RIBA Stage 3–4: for network layout validation and technical design

Tender & procurement: to reduce queries and show buildability

Commissioning phase: to simulate controls and phasing

Long-term asset management: to support performance tracking and fault diagnosis

Let’s Build It Twice — Digitally First

If you're designing a heat network, start with a smarter foundation. DTS helps you test, validate, and optimise before a shovel hits the ground.

RELATED READS

Explore our detailed guides on designing effective, future-ready district heating systems. Each article is written to help clients, developers, and stakeholders understand what great network design looks like in practice.